Dangerous Goods and Hazmat Packaging

Proper Packaging, Marking and Labeling are a critical aspect of preparing regulated goods for transportation. Choosing the right inner and outer packaging (or when regulations permit, single packaging) is the essential component for the safe transportation of Dangerous Goods. While shipping dangerous goods by air, ground or ocean, it is crucial to take into account the potential adverse effects of temperature, pressure and humidity variations, as well as the risk of damage due to vibrations and improper handling as well. For heavy shipments, additional requirements about how to palletize, shrinkwrap or crate the freight have to be considered.

DGM California can help with the design, selection and performing the packaging for all regulated goods and correctly marking and labeling the consignment.

After proper packaging, the outer packaging has to be labeled and marked correctly with the proper labels and other critical information that goes alongside the label. Additionally, if the shipment is declared as an Overpack or has special handling requirements, then the appropriate labels and markings have to be applied as well.

Dangerous Goods Packaging and Crating

Packaging compliance includes the correct choice of packaging for inner and outer packaging and determining if the goods should be palletized or crated.

Inner packaging type (bottles, jugs, cans), Material of construction (glass, metal, plastic) and the correct Packaging Quantity (in Liters, Kgs) all have to be per the Packing Instructions for the regulated product as these are all prescribed by the relevant regulations and these quantities vary for air, ocean and ground

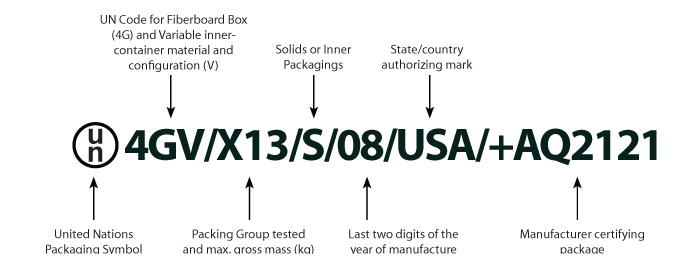

Outer packaging type (Box, Drums, etc) and Material of Construction (Steel, Plastic, Fiberboard, Wood) then need to be picked correctly and the maximum quantity limitation adhered to stay fully compliant with the regulations.

Some regulated products allow use of single packagings as well.

We stock a variety of UN approved packaging that are fully compliant with DG regulations including, ADR, IATA, IMDG. DGM California can help you with the selection of the correct packaging to ensure compliance and safe transport.

Dangerous Goods Marking and Labeling

The shipper is responsible for all necessary marking and labeling of each package of dangerous goods and each overpack, in compliance with the relevant regulations. A whole chapter is dedicated to the Markings and Labeling requirements in each regulatory handbook from DOT, IATA and IMO. These include detailed instructions on the quality, size of labels, size of the lettering for the labels and then specific instructions on where to place the labels and marks. Pictorial labels have to be accompanied with Word Labels that include the UN#, Proper Shipping Name and Quantity as per the regulations. Additional handling labels for Magnetized materials, Orientation labels for liquids, and advisory labels may be required depending on the needs.

DGM California carries labels for Hazard Classes 1 through 9 in Worded, Personalized, Blank, International Wordless and more. Our labels feature outstanding durability to withstand even the most harsh environments. Designed with long-life UV inks that resist peeling, these labels won't fade or fall off. They also help ensure compliance with DOT standards including the new design requirements of 49 CFR 172.407