Warehousing

DGM California has 100,000+ sq ft space in its warehouses in the Hayward and San Leandro area, close to Oakland port, FedEx Oakland hub and the San Francisco International (SFO) Airport and can accommodate any storage space, dock count and warehouse equipment requirements.

Challenges

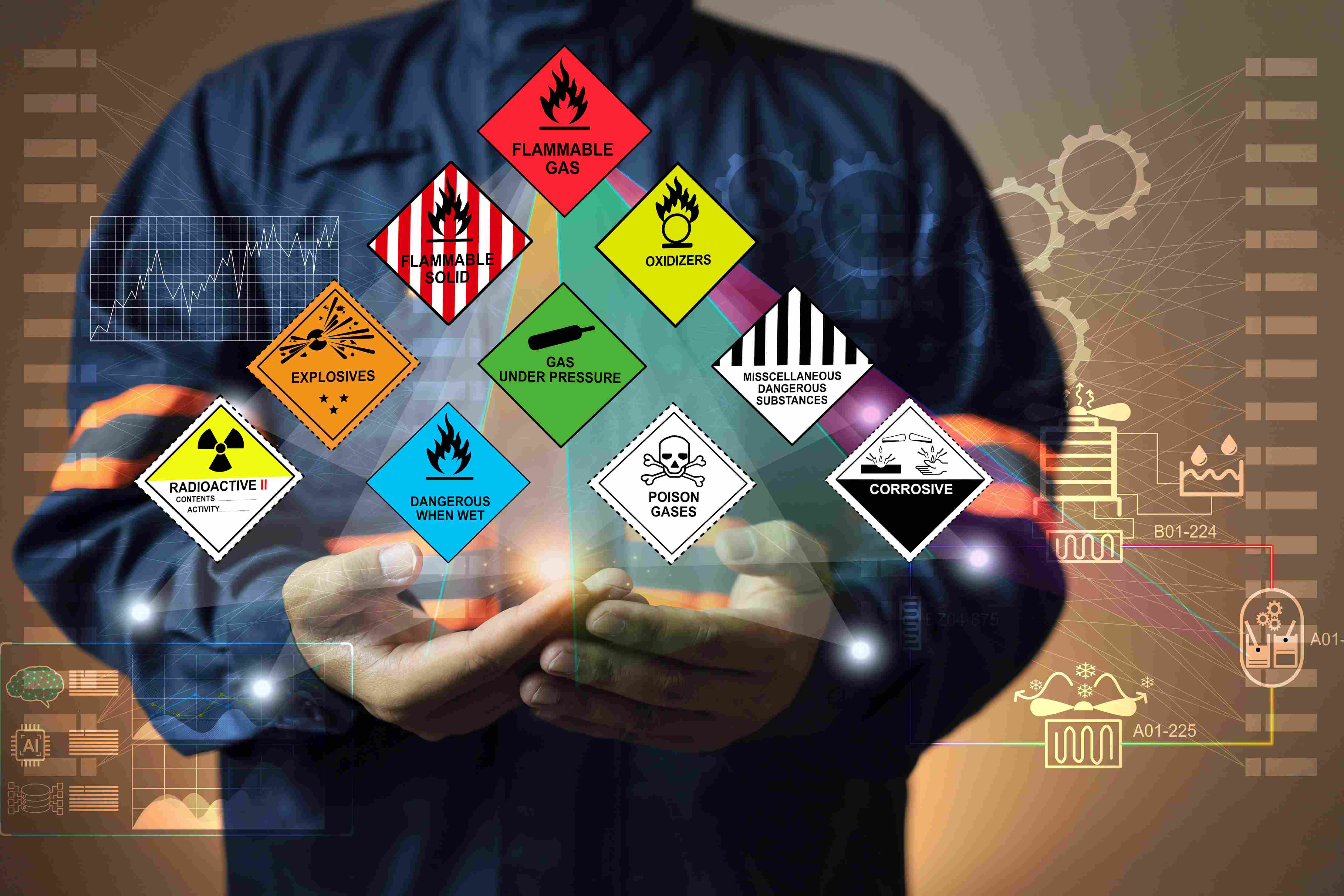

The most common challenges in warehousing of your regulated products include:

- Inappropriate product storage and segregation based on the chemical properties

- Mishandling causing leakage or spills or incidents

- Untrained personnel or lack of awareness of the dangerous goods

- Wrong markings and labeling of outbound goods

The storage of dangerous goods demands meticulous attention to safety protocols and regulatory compliance to

mitigate risks to personnel, property, and the environment. Whether dealing with flammable substances,

corrosive materials, or toxic chemicals, the storage of hazardous materials requires specialized facilities

and stringent procedures.

The storage of dangerous goods demands meticulous attention to safety protocols and regulatory compliance to

mitigate risks to personnel, property, and the environment. Whether dealing with flammable substances,

corrosive materials, or toxic chemicals, the storage of hazardous materials requires specialized facilities

and stringent procedures.

Solutions

DGM California has implemented best practices for the safe and secure storage of dangerous goods:

Facility Design and Infrastructure:- Designate separate storage areas based on the compatibility of hazardous materials to prevent potential chemical reactions and contamination.

- Install adequate ventilation systems to disperse potentially harmful vapors and gases. Incorporate fire suppression systems such as sprinklers to mitigate fire hazards and protect stored goods.

- Utilize secondary containment measures, such as spill trays, to contain leaks and prevent hazardous

- Accurately classify dangerous goods according to regulatory standards (e.g., UN classification, GHS) to ensure proper handling, storage, and transport procedures.

- Maintain up-to-date SDS for all hazardous substances stored on-site, providing essential information on chemical composition, hazards, handling precautions, and emergency procedures.

- Clearly label storage areas with appropriate hazard symbols, warning signs, and emergency contact information to facilitate safe handling and emergency response.

- Ensure proper temperature control and environmental conditions (e.g., humidity, ventilation) to prevent degradation or volatility of hazardous materials and maintain storage integrity

- Provide comprehensive training and certification programs for personnel involved in the handling, storage, and emergency response procedures for dangerous goods.

- Develop and regularly rehearse emergency response plans, including procedures for spills, leaks, fires, and chemical exposure incidents.

- Conduct routine inspections and remediation of storage facilities, equipment, and hazardous materials to identify potential hazards, leaks, or compliance issues.